Made in Cary, Illinois, these wood doors deliver proven radiation shielding and meet safety standards for use in medical, laboratory, and industrial settings.

Construction Details

-

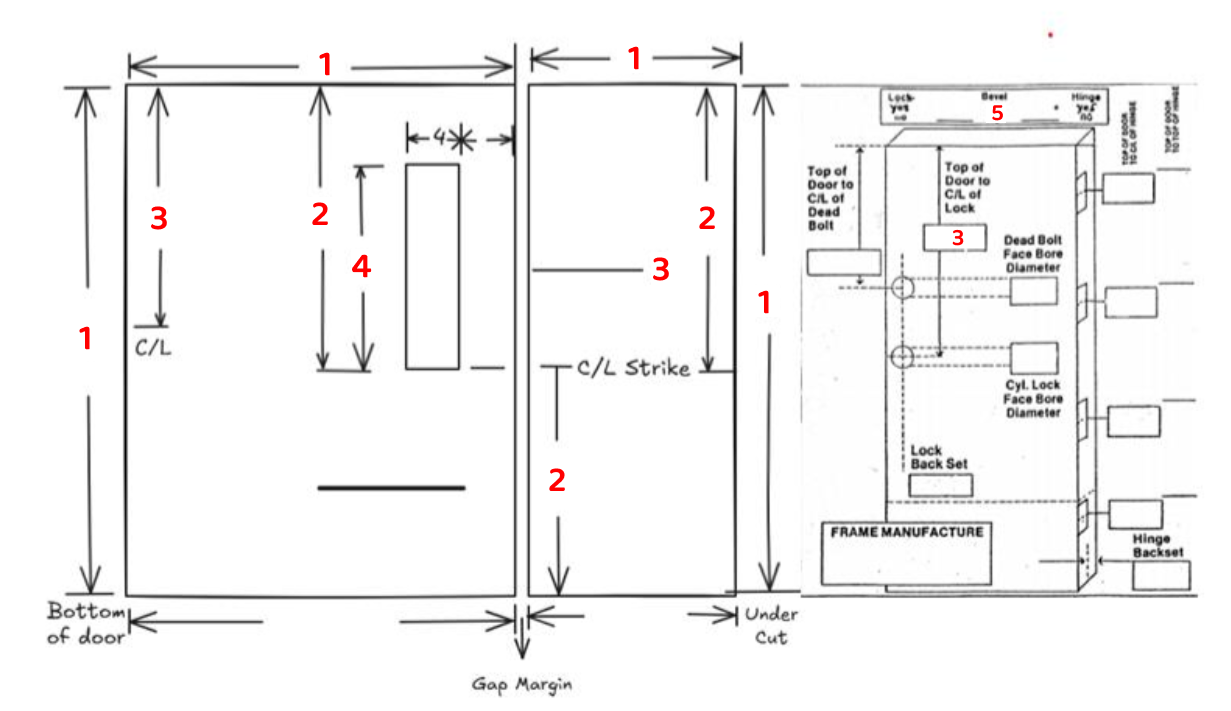

A single lead sheet runs the full width and height of each door, held securely between a divided solid core. This ensures continuous shielding coverage.

-

The internal assembly uses lead‑covered lag or through bolts placed every 8 inches and set 1.5 inches from edges. Rails and stiles are mechanically fastened to support the lead core.

Bonding & Finish

-

We use high‑grade casein glue on cross-banding and face veneer, pressed and cured overnight. This method produces strong adhesion and a smooth, durable finish.

-

Standard veneers are birch and oak; we will accommodate other wood species on request (additional time may be necessary).

Tailored to Your Project

-

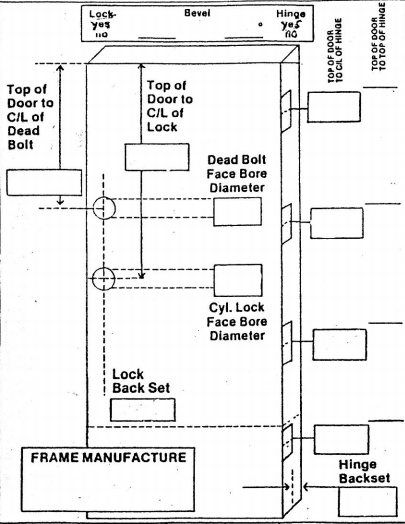

Specify exact size, lead thickness, and veneer type to match your project’s architectural needs.

-

Options include leaded glass viewing panels or light-blocking covers for visibility while preserving shielding integrity.

Built Locally with Care

-

Manufactured to exacting standards at our Cary, Illinois facility, with more than 40 years of experience in radiation shielding solutions.

-

Every door meets industry best practices for quality, reliability, and radiation protection.

Reviews

There are no reviews yet.